Development and research

submenu

An important part of our company is research and development, and service in the material field, which includes the following activities:

Research and Development

- Development of new tungsten materials. Tungsten heavy alloys WHA (tungsten heavy alloys), characterized by their high density and good machinability and corrosion resistance, are used as a base material for the production of shielding against radioactive radiation and for the production of newly designed missiles.

- Development and research on zirconium alloys, a universal material for the protection of nuclear fuel, has been going on continuously since the late 1960s. A collection of these long-term data collections is the basis for setting safety assessment criteria for nuclear reactor operation.

- Production of special compounds, such as uranium oxide, used as a glass dye additive. Depending on the uranium content, the color range ranges from yellow to yellow-green to yellow-brown.

- Development of β – titanium alloys for dental and orthopedic implants.

- Research on the durability of steel in the energy and chemical industries.

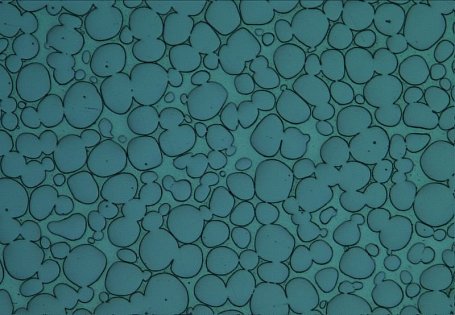

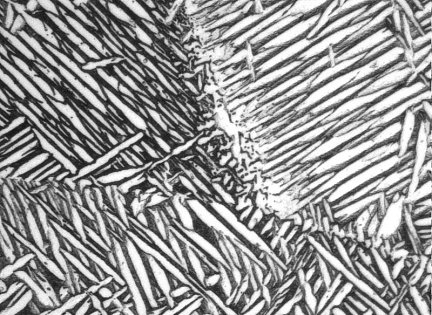

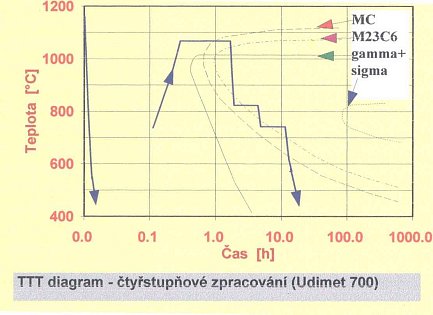

- Development of nickel alloys suitable for extreme operating conditions. These alloys are mainly used in aviation, aircraft engines, and chemical and glass operations.

Building on material development and research, we offer the following services

- Expert activity to extend the life of technological units operating under demanding operating conditions (eg in the chemical industry and in power engineering).

- Ensuring operational diagnostics with application of controlled aging programs.

- Investigation of causes of operational failures and accidents.

- Testing the mechanical properties of the material.

- Analysis of the structure and chemical composition of the material.

The great interest of our business partners in service work and expert evaluation, which follow the basic research program, is evidence of the high professional level of our workplaces.

A number of projects are partly financed by the Ministry of Industry and Trade (MPO) and the Technology Agency of the Czech Republic (TAČR).

The company’s laboratories have been selected by our EU partners for a wide-ranging international collaboration to experimentally assess the consequences of potential nuclear reactor disasters in terms of their core zone and nuclear fuel. This collaboration has a long-term perspective and represents a very important award for our company.