Industrial services

submenu

The portfolio of services offered to industry includes many different areas that UJP Praha, as deals with, for example:

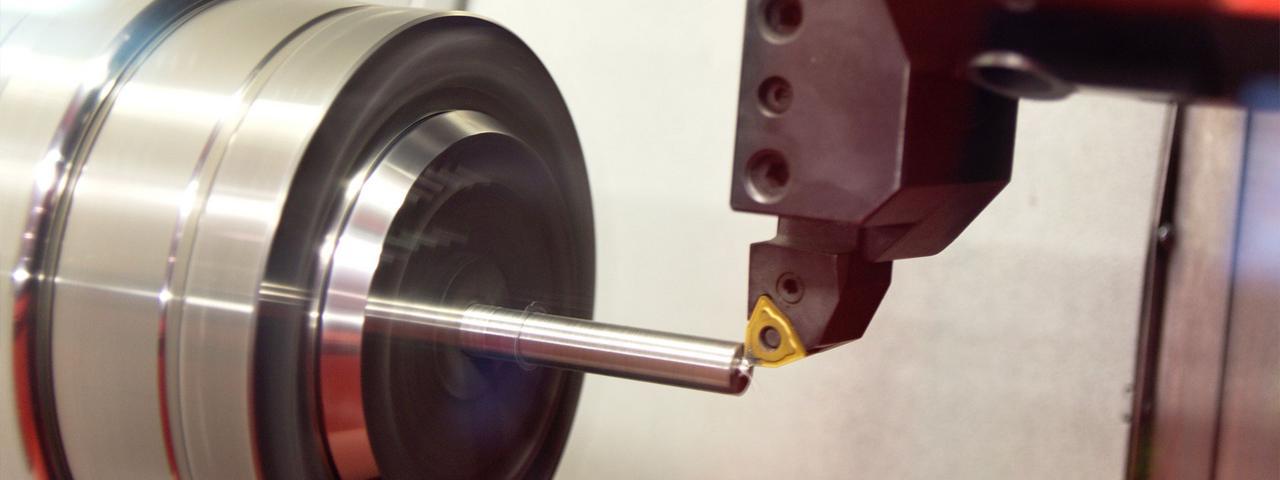

Engineering production

Equipment of production halls

- lathes, milling machines and horizontal boring machines

- locksmith workplaces including presses, benders, etc.

- prototype workshop with 3D printer

- welding workplace (TIG, MAG, electrode, flame) with required certification according to European standards (possibility of AISI certification)

Design office

- offers the development of the product from prototype production to the introduction of production production including consultation of technological possibilities

- offers the preparation of technological processes including welding (including WPS)

- works with modern CAD software (Pro / Engineer, Creo) including basic structural analysis

Construction accident

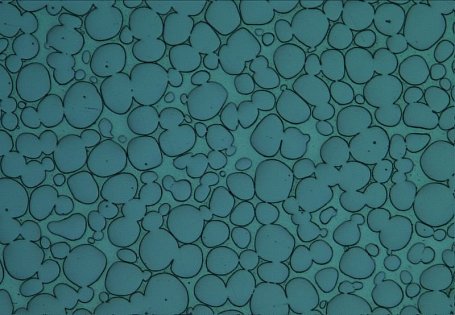

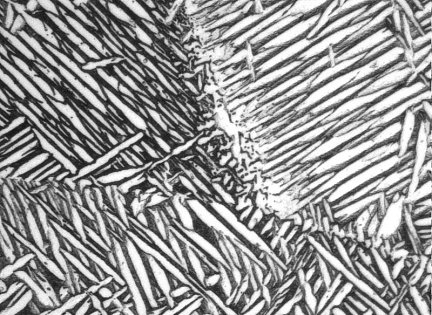

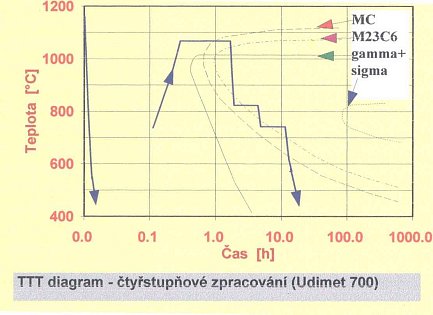

The construction accident field covers a wide range of activities dealing with the search of causes of failure in the material, causes of unsatisfactory mechanical and physical properties of the parts and products operated. Looks for causes of defects and causes of inappropriate material properties. Based on these, it makes recommendations for improving the condition.

Focus of programs

- determination of the causes of breakage (cracks) in the parts and products operated on the basis of microstructure analysis,

- mechanical properties and fractographic analysis of fracture surfaces

- elaboration of expert opinions, including nuclear energy

- determining the causes of increased wear of parts

- determining the causes of unsatisfactory product properties, optimizing material choice and heat treatment

- Material certificates including supplies for nuclear power

- We provide defectoscopy work

Defectoscopy

The non-destructive control of material called defectoscopy is a method of searching for surface and internal defects of the material without the necessity of breaking it. It is an important part of quality control and management in industry, applied not only in the control of building structures, in the mechanical or chemical industry but also in the nuclear industry, aerospace industry, etc.

Depending on the test method, defectoscopy is divided into different types, one of these are also radiological defectoscopy. The principle of this method is a control based on radiation of gamma-ray material using radionuclides, most often Iridium-192 and Selen-75.

Acceptance Testing and Long-Term Stability Testing

Acceptance testing is an initial inspection of an industrial device containing a source of ionising radiation performed after its installation or commissioning. The test is carried out by a person authorised by the State Office for Nuclear Safety (SÚJB) and is intended to verify the correct functionality of the device and to establish reference parameters for subsequent routine tests.

Long-term stability testing (LTST) represents a comprehensive periodic inspection (typically performed on an annual basis) of such devices. The test is also carried out by a person authorised by SÚJB and serves to verify that the device continues to meet all technical, operational, and safety requirements stipulated by applicable legislation.

UJP PRAHA as offers the following services in this field

- Tested dual delivery of defectoscopes 60, exerts dual 120, a power S4p RID-100

- supply of radiators, replacement of so-called over-storage, storage, disposal

- inspection of defectoscopy covers (long-term stability tests – ZDS), URZ certificate

- acceptance tests

- ADR transport

- we also offer: measurement of radiation in the workplace (dosimetric service), expert counseling services, supervising services, radiation protection training, emergency services

Irradiation Services for Materials Research

Our company provides specialized irradiation services dedicated to materials research, enabling detailed analysis and testing of materials exposed to controlled gamma radiation. We utilize irradiators based on our own product – the TERABALT radiotherapeutic cobalt irradiator, equipped with the radionuclide Co-60, capable of irradiation with dose rates ranging from 0.1 to 200 Gy/min and a total absorbed dose of up to 1 MGy. These services are essential for identifying changes in physical and mechanical properties of materials due to irradiation, optimizing material characteristics, and researching material resistance to radiation damage.