Tungsten materials

submenu

Tungsten materials

Tungsten pseudo alloys ( Wolfram Heavy Alloys) are produced by powder metallurgy aimed at the desired properties of the final product.

The basic component is tungsten, whose content ranges from 90 to 97% by weight. It is supplemented with nickel, iron and possibly cobalt in various proportions. The specific gravity of the pseudo-alloys ranges between 17.1 and 18.6 g / cm 3 , depending on the composition.

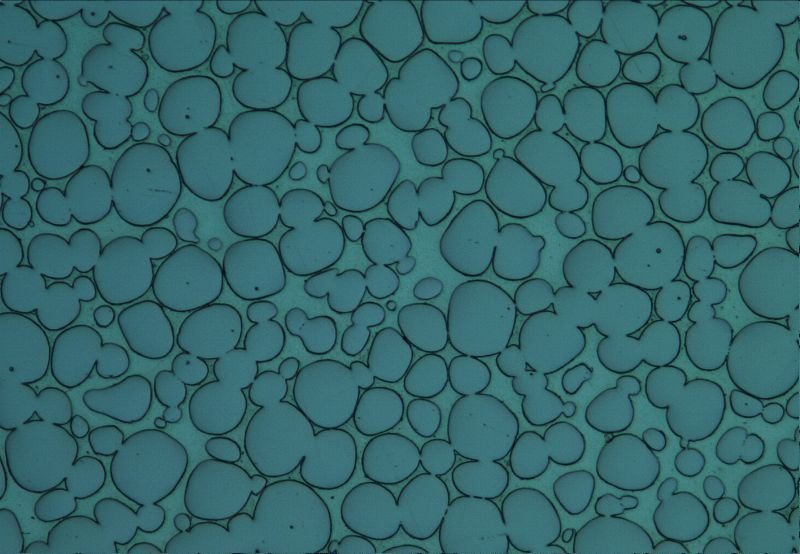

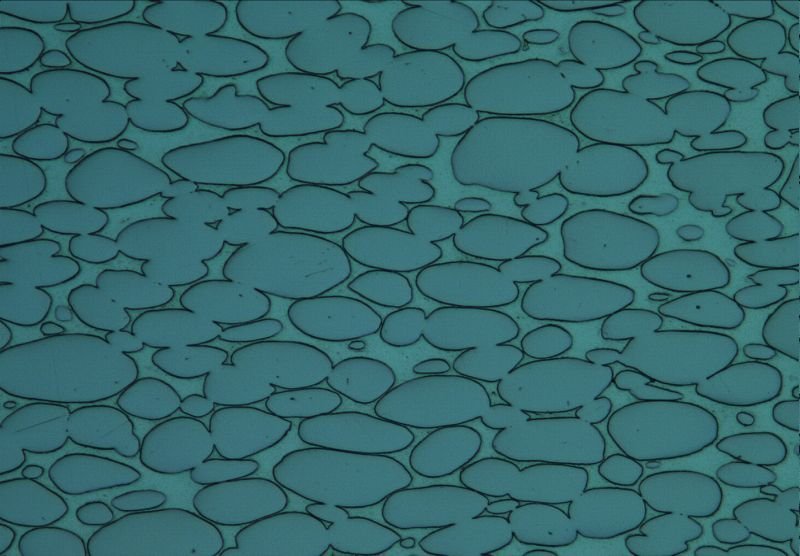

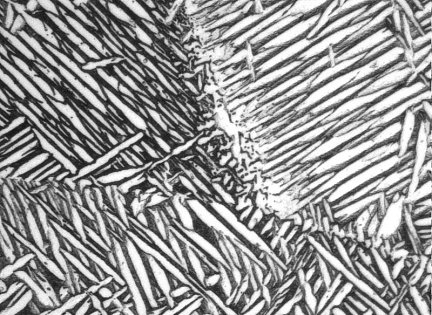

For WHA materials produced in the UJP PRAHA workplace and further technically applied, the table shows the range of mechanical properties and the corresponding structure in the initial and reinforced state.

Tungsten materials

Mechanical properties and structure of WHA materials after sintering and heat treatment

hardness HV 10

290 – 320

yield strength Rp02

> 700 MPa

strength limit Rm

> 1000 MPa

pity A5

> 15 %

Mechanical properties and structure of WHA materials after sintering and heat treatment

Mechanical properties and structure of WHA materials after molding with a total reduction of 30-40%

hardness HV 10

400 – 600

strength Rp02

1000 – 1400 MPa

strength limit Rm

1200 – 1700 MPa

pity A5

> 5 %

modulus of tensile modulus E

with increasing W content

330 – 380 GPa

Mechanical properties and structure of WHA materials after molding with a total reduction of 30-40%

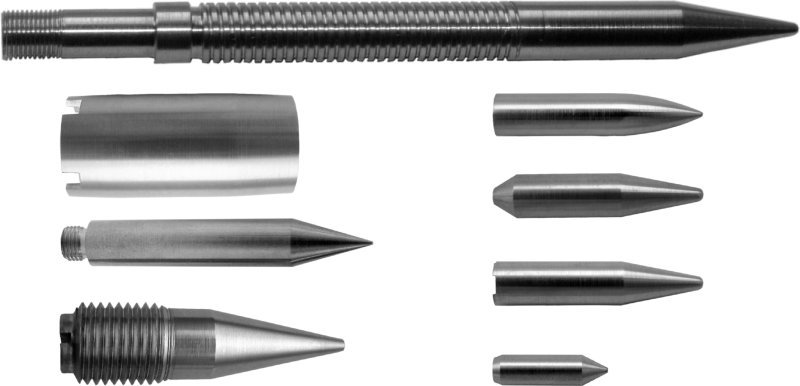

The department of tungsten materials at UJP PRAHA as, currently manufactures components for radiation shielding and oncological irradiators. In the field of ammunition application, the penetrating subcaliber penetrators (9mm, 12.7mm, 20mm and 30mm) are available. The maximum dimensions of sintered blanks are given by a diameter of 360 ° and a height of 250 mm (weight ~ 250 kg).

WHA materials currently fully substitute uranium alloys for various industries. Their advantage is excellent corrosion resistance, they are well workable, they are not environmental burdens.

Usage is very variable, it includes a number of industries:

- manufacture of radiation shielding, containers for transport of radioisotopes, collimation systems for oncological irradiators

- penetrators spanning high strength armor

- balancing weights in aviation

- highly stiff tool holders with low vibration and drill rods